Company news

RadRock launched the RF front-end receiving module with advanced packaging process

2022.12.23

As a well-known RF device supplier in the industry, with strong R&D strength and front-end design experience, RadRock actively deploys and expands RF front-end products with PA as the cornerstone, closely follows the general trend of modular market, adheres to the concept of continuous innovation, actively practices and launches diversity receiving modules based on advanced packaging processes to meet the needs of consumer products such as mobile phones, tablets, IoT IoT modules, etc., and provides customers with comprehensive solutions at both ends, and further accelerates the process of localization and replacement of RF modules.

With the continuous development of 5G, mobile phone terminal products have richer functional requirements, cellular from 5G down compatible with 4G, 3G, and 2G, while GPS, WIFI, BT, NFC are available, flagship models will also have UWB, satellite communications and other powerful communication capabilities, not only that, users also expect stronger battery life, lighter and more beautiful appearance, which has formed a situation where more and more functions, but there is no corresponding increase in enough space for the RF front-end system layout. Therefore, in order to meet the extremely complex terminal design challenges, the use of highly integrated RF modules has become an inevitable industry trend.

At the same time, the cellular Internet of Things market has the same demand, highly integrated RF modules have innate advantages, small area, simple debugging, can help designers accelerate product development, greatly improve the simplicity of product development, shorten time to market and reduce costs, which makes it possible for customers to launch smaller and more competitive products. In order to support customers to develop forward-looking products, RadRock always keeps abreast of the latest market trends and uses continuous innovation in technology and design to meet customer needs.

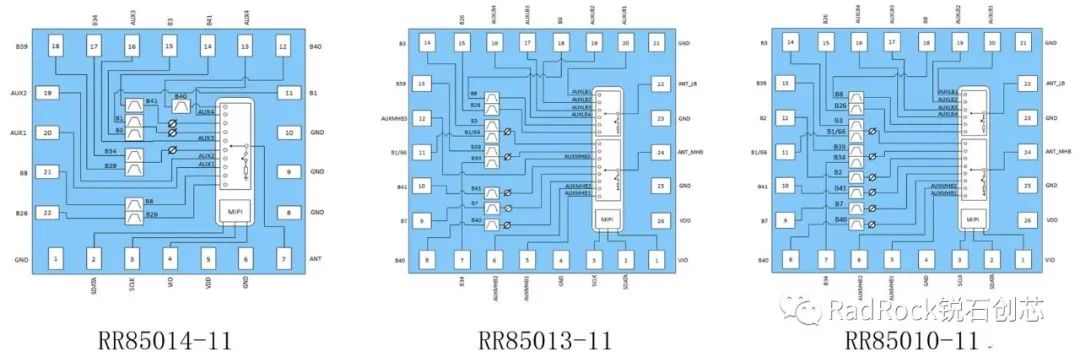

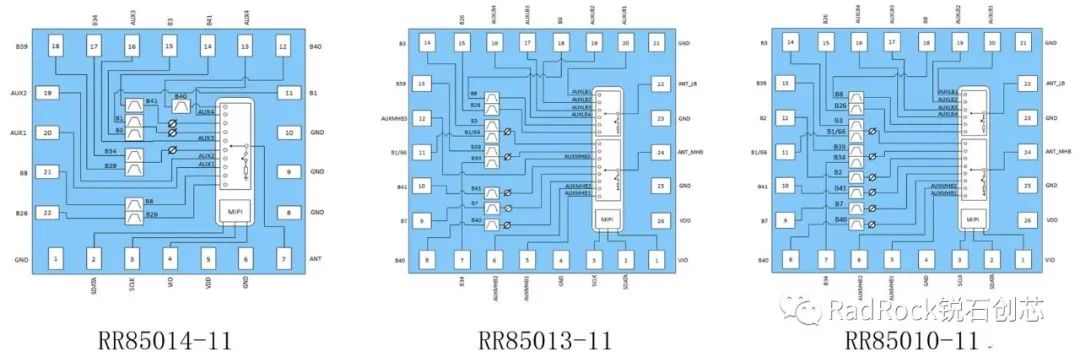

In response to such market and user needs, RadRock has launched a series of products on the diversity module: RR85014-11, RR85013-11 and RR85010-11, and will soon launch DiFEM products designed for domestic SA Only to meet the large needs of existing and future markets in China and overseas, this series of products integrates single-pole, multi-throw switch (SPnT) or double-pole, multi-throw switch (DPnT) and SAW filter. Advanced bare die packaging technology is adopted to improve integration and reduce product cost.

1、Functional block diagram of the DiFEM series of products

2、Features of the DiFEM series

- Coverage of some major frequency bands at home/overseas

Band66(1)/2/3/26(5)/7/8/34/39/40/41F

- Integrated Bare Die filter eliminates the need to integrate additional SMD devices

- Integrated antenna large switch

- Support multiple LB, MHB AUX ports, providing flexible band expansion

- Switch Multi-on function supports multiple CA combinations

- MIPI 2.1 communication protocol

- LGA package

- Two sizes

3.2mmx3.0mmx0.7mm

3.7mmx3.2mmx0.7mm

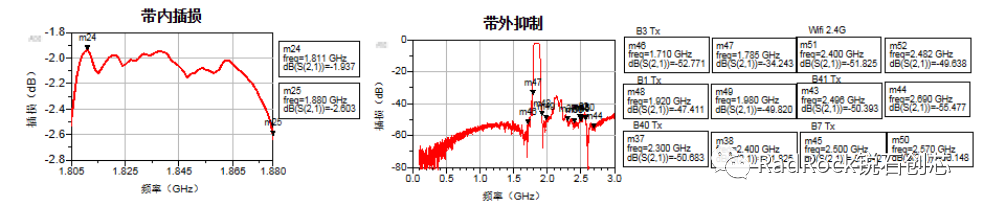

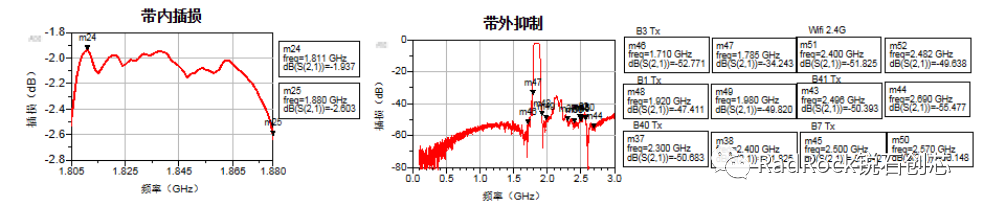

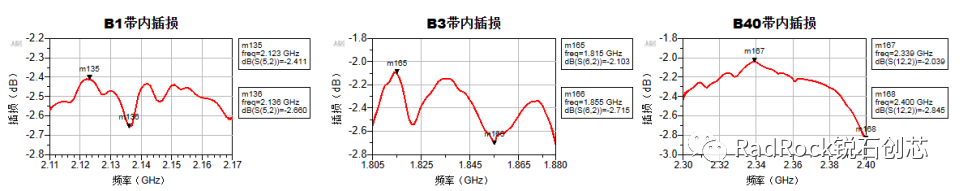

3、Measured data

Band_3 single-open mode as an example:

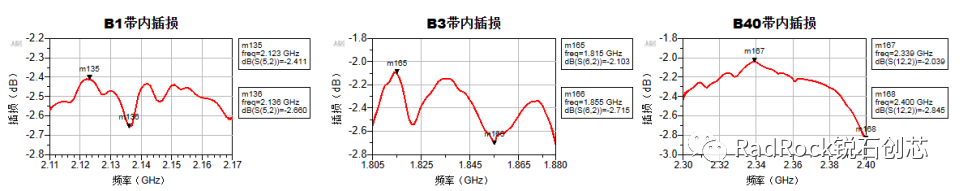

Band_1 the +3+40 CA mode as an example:

4、Design capabilities

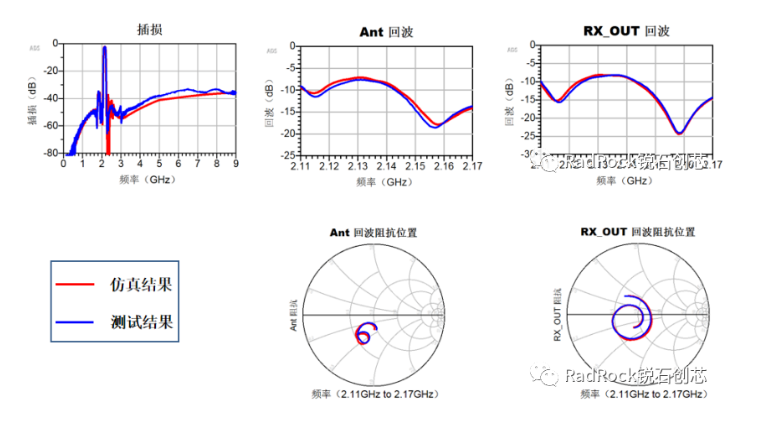

In the process of product development, RadRock pays great attention to the joint design between internal devices, combines simulation and actual measurement and continuous optimization and polishing, effectively reduces the matching loss between internal devices, meets extremely high process requirements, and Die matching also makes the whole design avoid the use of SMD devices, and the performance shows strong stability.

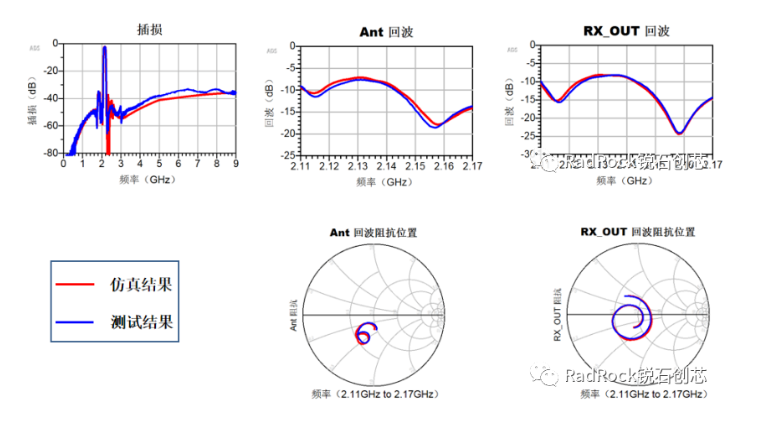

The R&D team of RadRock DIFEM has developed a perfect simulation process and method, and obtained a high degree of simulation and test consistency. The accuracy of simulation facilitates the optimization of product performance design and minimizes the time for laboratory commissioning, which in turn shortens the module design cycle.

The figure below is an example of a generic comparison of Band_1, and it can be seen that there is a high degree of alignment in terms of insertion loss, out-of-band rejection, and echo.

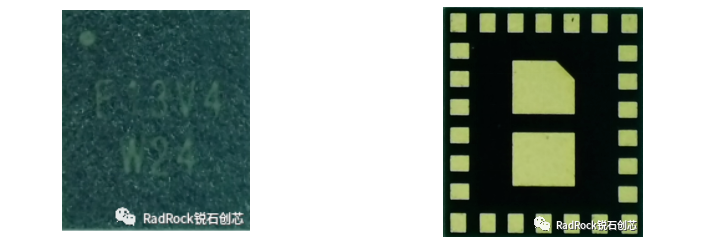

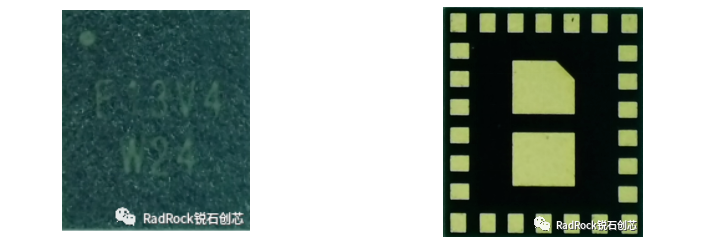

5、Advanced packaging process

Different from the traditional CSP and WLP packages used by other manufacturers in the industry, the packaging used by RadRock is to package bare chips such as filters and switches in the module, eliminating the need for CSP packaging or WLP packaging before the module packaging process in which a single filter in common modules needs to be packaged by CSP or WLP. It not only greatly reduces the production and manufacturing process, reduces the cost, but also reduces the volume of the module and improves the integration of the module; On the other hand, the simplification of structure and process makes the manufacturing process of the module more compatible, the reliability ability of the module itself is better, and the high-temperature repair performance is more stable.

It has the following advantages:

High integration: The bare chip is directly packaged inside the module, reducing the module size

Thinner module thickness: Full FC bare chip mounting, can have lower product thickness

General packaging process: The main packaging process is common to SIP packaging equipment, which is convenient for capacity expansion and deployment

High reliability: It can withstand no less than 5 times of reflow production process and meet the corresponding reliability requirements

New product expectations

With the continuous development of 5G, mobile phone terminal products have richer functional requirements, cellular from 5G down compatible with 4G, 3G, and 2G, while GPS, WIFI, BT, NFC are available, flagship models will also have UWB, satellite communications and other powerful communication capabilities, not only that, users also expect stronger battery life, lighter and more beautiful appearance, which has formed a situation where more and more functions, but there is no corresponding increase in enough space for the RF front-end system layout. Therefore, in order to meet the extremely complex terminal design challenges, the use of highly integrated RF modules has become an inevitable industry trend.

At the same time, the cellular Internet of Things market has the same demand, highly integrated RF modules have innate advantages, small area, simple debugging, can help designers accelerate product development, greatly improve the simplicity of product development, shorten time to market and reduce costs, which makes it possible for customers to launch smaller and more competitive products. In order to support customers to develop forward-looking products, RadRock always keeps abreast of the latest market trends and uses continuous innovation in technology and design to meet customer needs.

In response to such market and user needs, RadRock has launched a series of products on the diversity module: RR85014-11, RR85013-11 and RR85010-11, and will soon launch DiFEM products designed for domestic SA Only to meet the large needs of existing and future markets in China and overseas, this series of products integrates single-pole, multi-throw switch (SPnT) or double-pole, multi-throw switch (DPnT) and SAW filter. Advanced bare die packaging technology is adopted to improve integration and reduce product cost.

1、Functional block diagram of the DiFEM series of products

2、Features of the DiFEM series

- Coverage of some major frequency bands at home/overseas

Band66(1)/2/3/26(5)/7/8/34/39/40/41F

- Integrated Bare Die filter eliminates the need to integrate additional SMD devices

- Integrated antenna large switch

- Support multiple LB, MHB AUX ports, providing flexible band expansion

- Switch Multi-on function supports multiple CA combinations

- MIPI 2.1 communication protocol

- LGA package

- Two sizes

3.2mmx3.0mmx0.7mm

3.7mmx3.2mmx0.7mm

3、Measured data

Band_3 single-open mode as an example:

Band_1 the +3+40 CA mode as an example:

4、Design capabilities

In the process of product development, RadRock pays great attention to the joint design between internal devices, combines simulation and actual measurement and continuous optimization and polishing, effectively reduces the matching loss between internal devices, meets extremely high process requirements, and Die matching also makes the whole design avoid the use of SMD devices, and the performance shows strong stability.

The R&D team of RadRock DIFEM has developed a perfect simulation process and method, and obtained a high degree of simulation and test consistency. The accuracy of simulation facilitates the optimization of product performance design and minimizes the time for laboratory commissioning, which in turn shortens the module design cycle.

The figure below is an example of a generic comparison of Band_1, and it can be seen that there is a high degree of alignment in terms of insertion loss, out-of-band rejection, and echo.

5、Advanced packaging process

Different from the traditional CSP and WLP packages used by other manufacturers in the industry, the packaging used by RadRock is to package bare chips such as filters and switches in the module, eliminating the need for CSP packaging or WLP packaging before the module packaging process in which a single filter in common modules needs to be packaged by CSP or WLP. It not only greatly reduces the production and manufacturing process, reduces the cost, but also reduces the volume of the module and improves the integration of the module; On the other hand, the simplification of structure and process makes the manufacturing process of the module more compatible, the reliability ability of the module itself is better, and the high-temperature repair performance is more stable.

It has the following advantages:

High integration: The bare chip is directly packaged inside the module, reducing the module size

Thinner module thickness: Full FC bare chip mounting, can have lower product thickness

General packaging process: The main packaging process is common to SIP packaging equipment, which is convenient for capacity expansion and deployment

High reliability: It can withstand no less than 5 times of reflow production process and meet the corresponding reliability requirements

New product expectations

In 2023, RadRock will also launch a new generation of dual-antenna small-size DiFEM RR8501x-11 suitable for domestic SA Only, and will integrate B28F filters, further simplifying the design of external B28F filters that customers currently need, which will bring obvious benefits to customers in terms of cost and space.

Related news